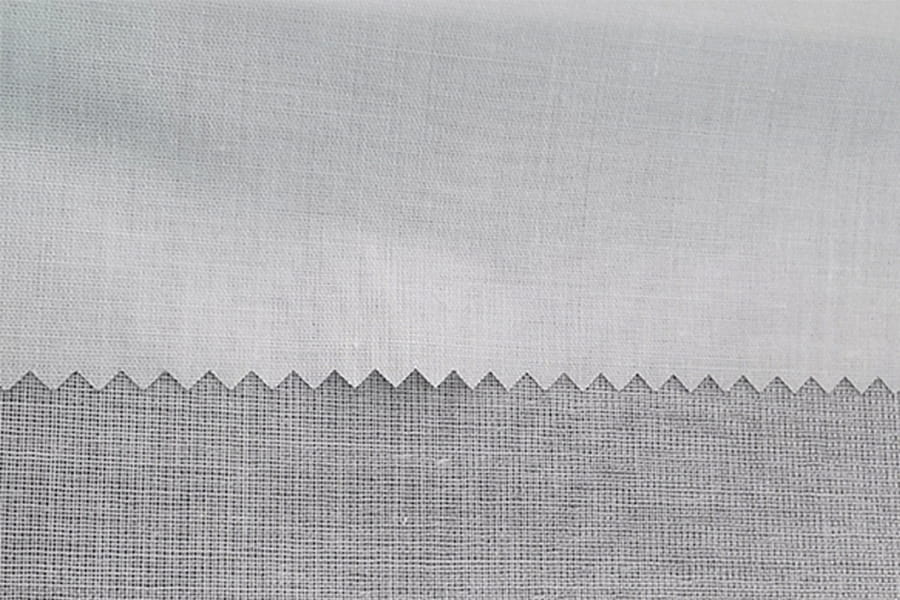

Ad vinculum Polyester Fusible Interlining Efficaciter, temperatus temperatus, pressura, et tempus per vinculum processus est discrimine. Hae factores debet esse optimized secundum ad tenaces genus, interlining structuram (textile, nonwoven, aut knitted) et fabricae ad quod interlining applicantur.

Temperatus iudicium

General range: Polyester interlining typically postulat temperaturis inter CX ° C et CLXXX ° C (CCXXX ° F CCCLVI ° F) adhaelda adhaesives CXL ° C et CXL. Hi sunt idoneam ad delicata textilia prone ad calor damno.high, solet adhesives, quia gravibus-officium applications vel fabricas requiring magis robustorum adhaesionem, altiori vinculum temperaturis CL ° C ° C ° C ° C ° C ° F.

Temperature Consistency: Uniform heat distribution is crucial across the bonding surface to prevent uneven adhesion, bubbling, or delamination.Fabric Sensitivity: Ensure that the temperature does not exceed the melting or distortion threshold of the outer fabric, particularly with synthetic or heat-sensitive materials. Using a torcular panno vel Teflon sheet potest ne neuter aut glossatione super delicata textilia.

Pressura iudicium

Optimal Range: De Bonding Processus plerumque postulat pressura inter 0.2 MPA et 0,5 MPA (II ad V kg / C²) et mollis textilia ad vitare creando impressiones aut mutat et fabricae in texture.

Heavy or Textured Fabrics: Higher pressure is necessary for thick or textured fabrics to ensure the adhesive penetrates into the fabric weave and creates a strong bond.Uniformity: The pressure must be evenly distributed across the entire surface to avoid weak spots, wrinkles, or air pockets in the bonded fabric.

Tempus sub calor et pressura

Generalis Duration: De Bonding Processus plerumque accipit X ad XX seconds sub temperatum calor et presert.longer habitare temporibus sunt utilis est gravius textilia vel cum per interlinings cum summus adhaelsives.

Shorter habitare tempora malle ad leve textilia ad minimize periculo damnum vel distortion.Adjustability, quod habita tempus sit adaequatum secundum fabricae crassitudine, tenaces genus, et de ratione vestimento scriptor application.

Pre-Bonding Praeparatio

Fabricae praeparatio: ensure fabricae mundus sicca et pulvis vel finiatur ut impediat adhaesionem. Pre-pressing the fabric can smooth wrinkles and stabilize it for bonding.Interlining Placement: Align the interlining carefully on the wrong side of the fabric to avoid misalignment or misplacement during the bonding process.Testing: Conduct a trial on a fabric sample to verify the settings and ensure the desired bond strength without fabric distortion.

Refrigerationem et post-bonding considerations

Refrigerant sub pressura: patitur in bonded fabricae ad refrigeret in levi pressura ad minus 5-10 seconds ad stabiliendum in tenaces. Hoc adjuvat vinculum et prohibet bubbling vel Delamination.inspicition: reprehendo pro consistent vinculum trans superficiem, cursus non sunt infirmi areas et signa de tenaces defectum.

Variationes secundum fabricae et applicationem

Extendam aut knyt textilia: Usus interlinings cum aliqua elasticitate et vitare princeps pressura, ut extendas aut detortis fabric.delicate textilia: inferioribus temporibus, curare fortis et pressura in sistens descripturae, ut fortis et cum longiores sistens.

Per tailoring temperatus, pressura, et habitant tempore ad propria materiae implicari, Polyester Fusible interlining vinculum efficaciter creando firmum, durare consummavi quod sit vestiméntum in structuram et speciem. Propriis praeparatio, testis, et refrigerationem sunt essentialis ad consequimur results in utroque magna-scale productio et parva-scale applications.

LENTITUDO